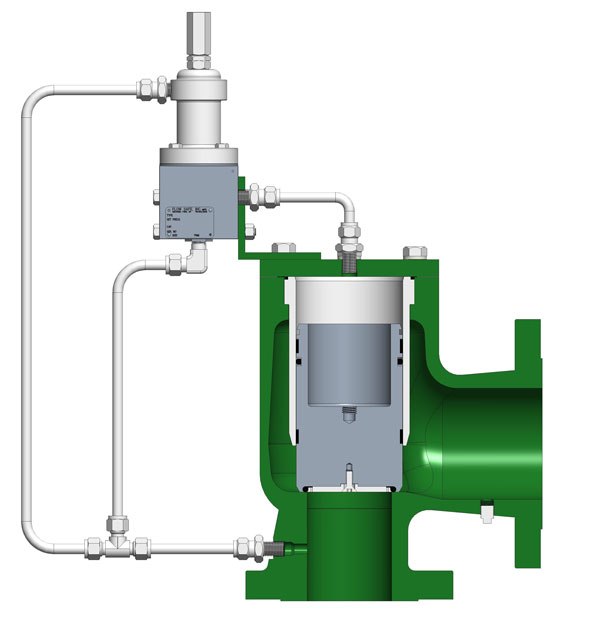

Vacuum (F70VP)

Vacuum Relief Valve

A variation of the F70PR pilot operated relief valve (shown on the Pressure Relief Valves page), with pilot tubing rearranged to support vacuum operation. Atmospheric pressure, present at the valve inlet or outlet, depending on the application, provides the lift force required to open the main piston once the vacuum set point is reached. Backflow preventers are available to prevent valve opening on loss of vacuum. Flow Safe vacuum valves have better performance and better design strength versus weight loaded vacuum valve manufacturers.

FEATURES

- Weighted-piston (fixed set) or pilot operated (variable set)

- Soft seated (Elastomer)

- Full bore orifice

- Piston lift at designated vacuum set point

- Rugged, simple, light-weight design

- Corrosion resistant trim (aluminum or stainless steel)

- Leak tight under positive operating conditions, upon request

- Ability to handle large flow rates

- Minimal installation and maintenance costs

- Can be mounted with inlet or outlet to process (user specified)

APPLICATIONS

- Vacuum protection

- Low pressure storage tanks

- Evacuation systems

Service Envelope

| Connection Sizes Custom sizes & dual outlet bodies available on request | 1.5” x 2” - 12” x 16” (38mm x 50mm - 300mm x 400 mm) |

| Set Pressure Ranges See F70VP Catalog for size specific ratings | 0.36 to 14.7 psiv (-0.025 to -1.01 barg) |

| Temperature Ranges | -65 to 400°F (-54 to 204°C) |

| Orifice Area Range | 1.770 – 111.87 in2 (1142 – 72174 mm2) |

| End Connections Custom types available on request | Standard: Female NPT (1.5” x 2” size only) Integral ASME RF Flanged (150# inlet/outlet) |

| Materials of Construction Custom available for service or on request | Carbon Steel w/ aluminum or stainless trim Aluminum (1.5” x 2” size only) |

| Seat Materials Custom available for service or on request | Elastomer: Buna-N, Viton® (FKM) or equal, EPR/EPDM |